"MEKO & KO" offers seaming services for processing and preparation of metal sheets for further assembly!

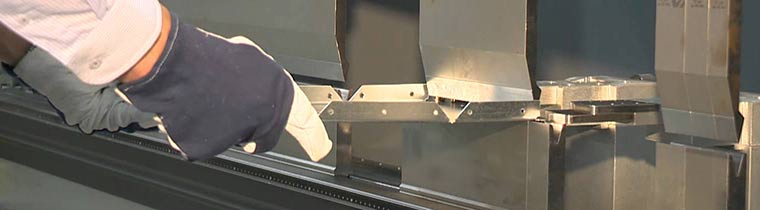

Seaming plays an important role in the processing and preparation of various metal constructions. Seaming, also referred to as hemming, is bending and closing of metal sheets.

Seaming is different from the ordinary bending in that the metal sheet is bent and pushed closed at up to 180 degrees, and this metalworking technology is primarily used for postprocessing of metal components for different security reasons - to improve security (for example, by protecting from getting injured by sharp, rough edges), to strengthen the structure itself, as well as to improve its overall visual appearance.

A side-process of seaming is the joining of sheets - known as hemming, when edges of a sheet are bent and joined together - shut with the "end-jointing" technique without using any seams or rivets for the spots where usually fusing or stapling are used. That is why seaming is sometimes also referred to as stapling.

Metal seaming equipment

Seaming requires a high pressure press and the use of various auxiliary tools in order to perform high-quality bending of sheets in various angles.

In the "MEKO & KO" metalworking plant we use the following seaming equipment for the processing of metal sheet edges:

Technical specifications:

- Manufacturer: HACO - Denmark

- Model: PPH 30/180

- Maximum sheet thickness: 2 mm

- Pressing force: 1800 kN

- Chamfer length: 2050 mm

- Space between columns: 2550 mm

- Working table height: 1010 mm

- Maximum piston trajectory length: 150 mm

- Column width: 250 mm

- Adjustable speed: 50 mm/sec

- Seaming speed: 6 mm/min

- Reverse speed: 65 mm/sec

- Working table width: 200 mm

- Power: 11.0 kW

- Dimensions: L-W-H 3.1 x 1.75 x 2.8 mm

Bending diversity!

Seaming requires using a lot of auxiliary tools and a high-pressure pressing machine, in order to perform high-quality bending of sheets into precise angles, therefore a correct, understandable and schematic drawing is of great importance to a high-quality final result.

Seaming is an important step in the metalworking process in order both to prepare separate metal parts for further processing and assembly, and also to finish ready-made constructions!

Seaming is very important in the manufacturing of such metal constructions as metal doors, mailboxes, window sills, skirting boards, profiles and other types of finishes.

"MEKO & KO" performs accurate and diverse seaming services on ferrous metal, aluminium and stainless steel sheets.